Abel’s proprietary “Chemical Polishing” for shapes difficult to treat by electropolishing

Chemical polishing immerses the workpiece in a special solution and dissolves the surface through a chemical reaction.

Like electropolishing, it polishes formed stainless parts, but chemical polishing is well suited for removing foreign matter and scale, and for cleaning on complex geometries.

If electropolishing has been ruled out due to shape or construction constraints, consider chemical polishing.

Key Characteristics of Chemical Polishing

1: Effects Comparable to Electropolishing

Our chemical polishing achieves a highly aesthetic glossy finish that is difficult for others to match.

It delivers smoothing, gloss increase, improved corrosion resistance, surface cleaning, and enhanced cleanability on a level comparable to electropolishing.

2: Suitable for Small Lots

Because there is no need to set up electrodes or jigs as in electropolishing, initial costs can be contained, making it suitable for small-lot processing.

3: Uniformity That Is Difficult with Electropolishing

Electropolishing depends on electrodes/jigs and the ability to distribute current uniformly; complex shapes may not be processed evenly.

Chemical polishing uniformly dissolves wetted areas, enabling even finishing on complex geometries.

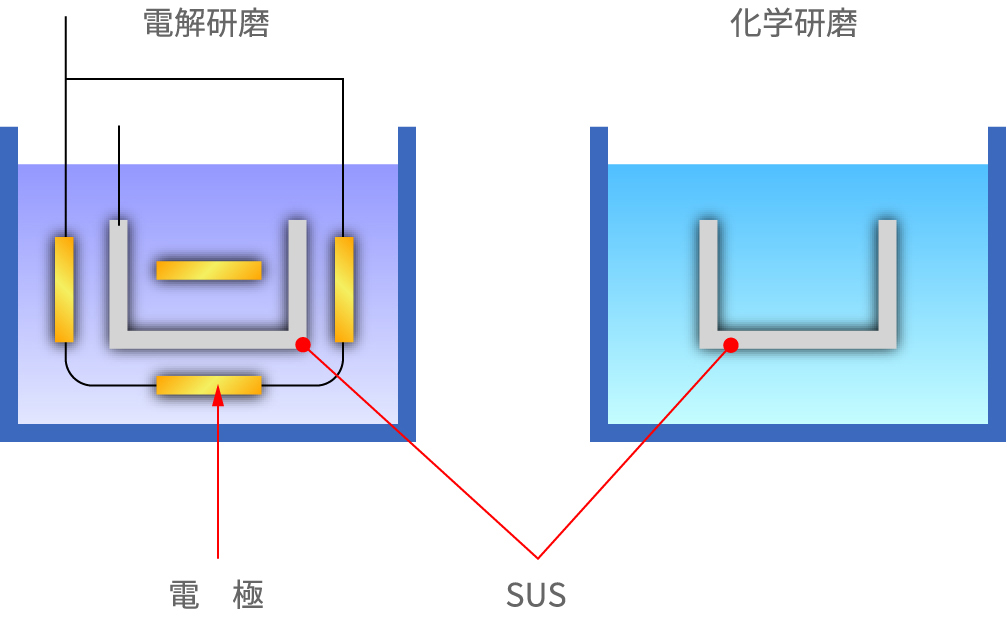

Comparison of Electropolishing and Chemical Polishing Methods

In electropolishing (left), stainless steel (SUS) is connected to electrodes and polished by electrical current in an electrolyte.In chemical polishing (right), the surface is dissolved uniformly through a chemical reaction without electrical input.

Unlike electropolishing, which requires complex electrode and jig setup, chemical polishing does not.

Processable Size

| Specification | Details |

|---|---|

| Maximum dimensions (mm) |

500H × 850W × 900L |