Anti-Reflection Performance

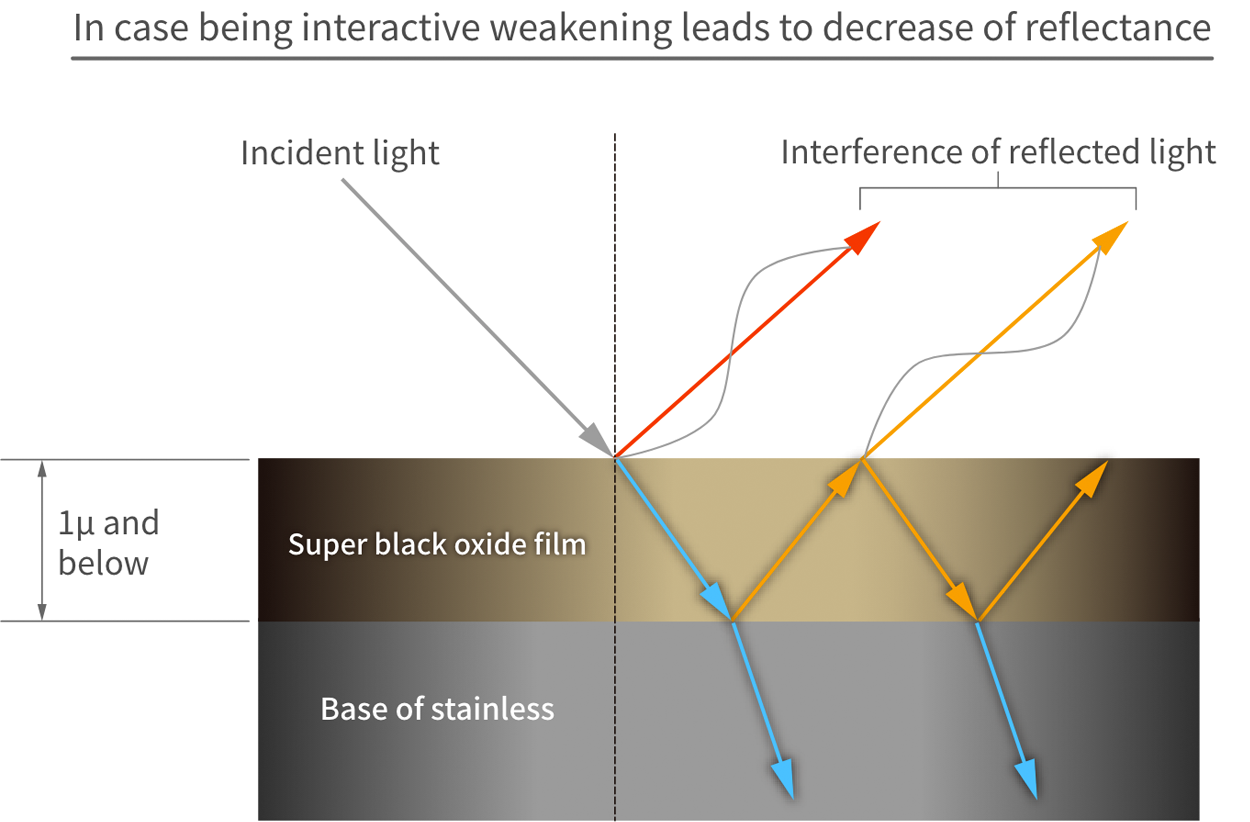

Abel Black® creates black film on the stainless surface by growing the passivated film which is intrinsic property of stainless and identical ingredient to oxide film by means of the effect of electricity and the oxidation power of pharmaceuticals.

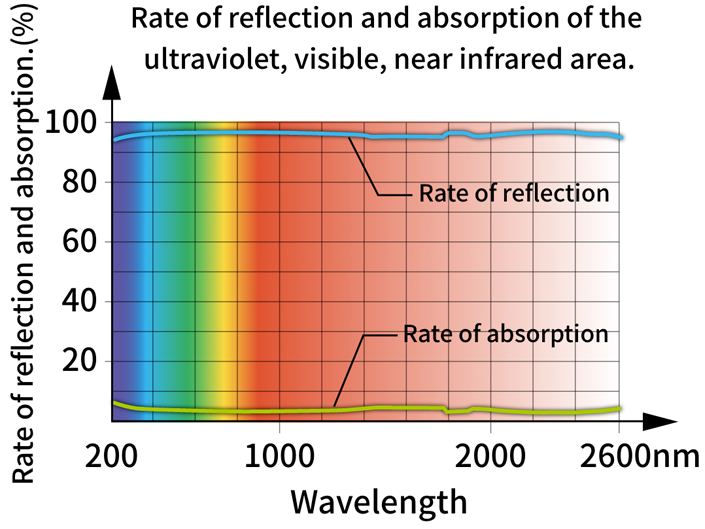

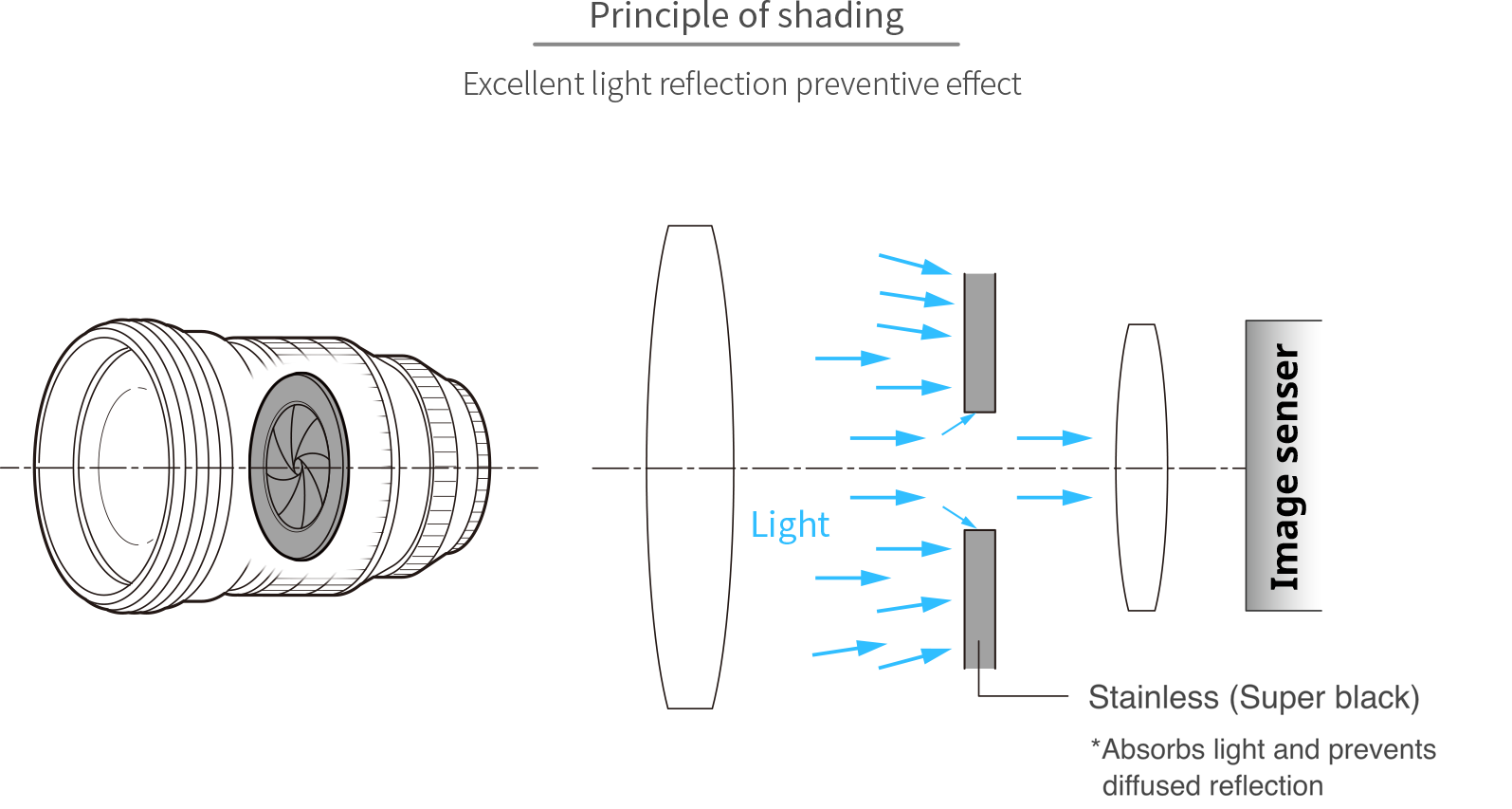

Black color weakens reflected lights and decrease the reflectivity of lights, since black absorbs all lights of wavelength.

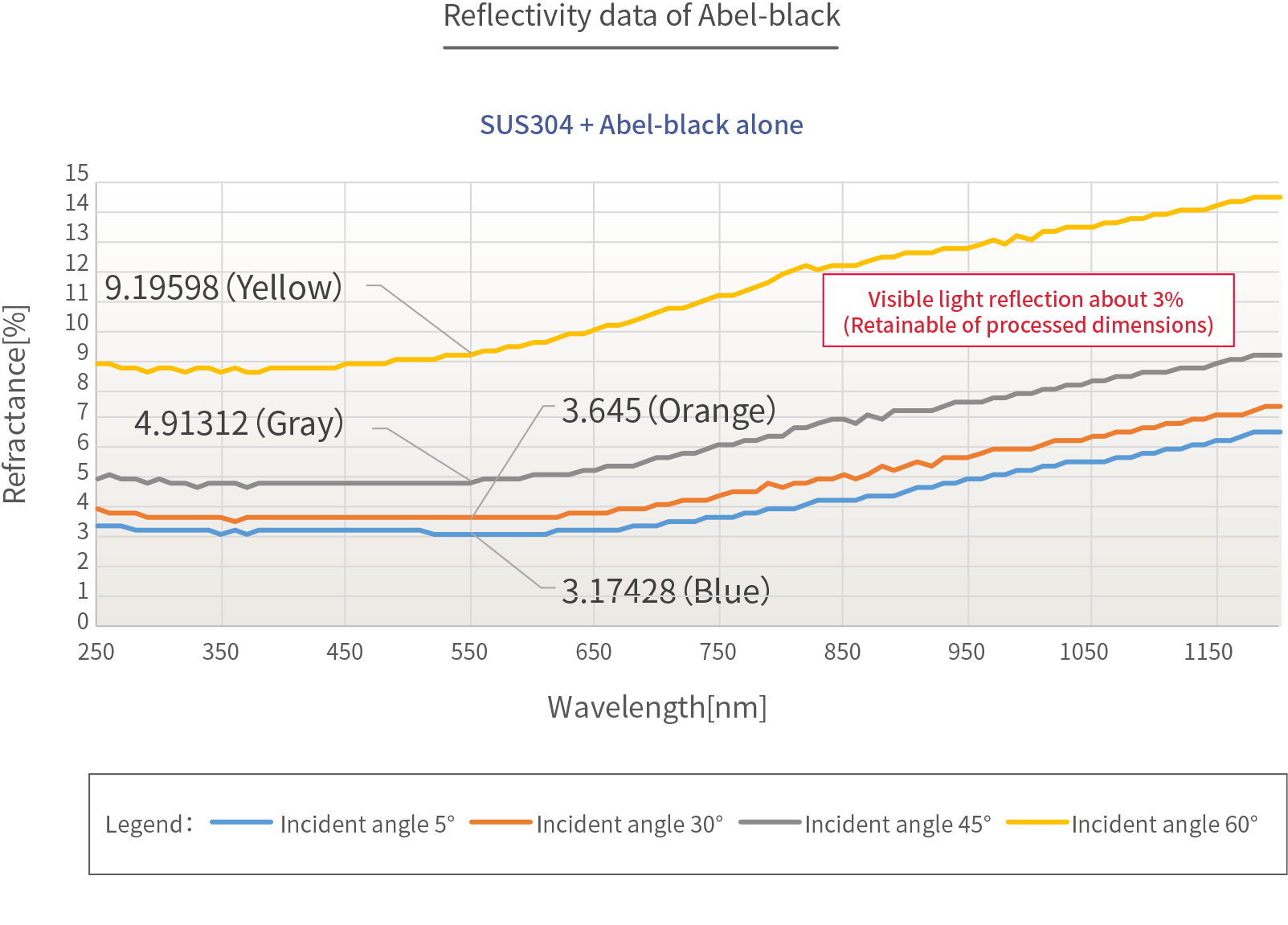

Consequently, the Abel Black® treated stainless displays a supreme effect of reflection of light.

Also, Abel-black transforms into the device that avails to display high quality picture, because it creates the film uniformly which achieves the high efficiency preventive effect of light reflection.

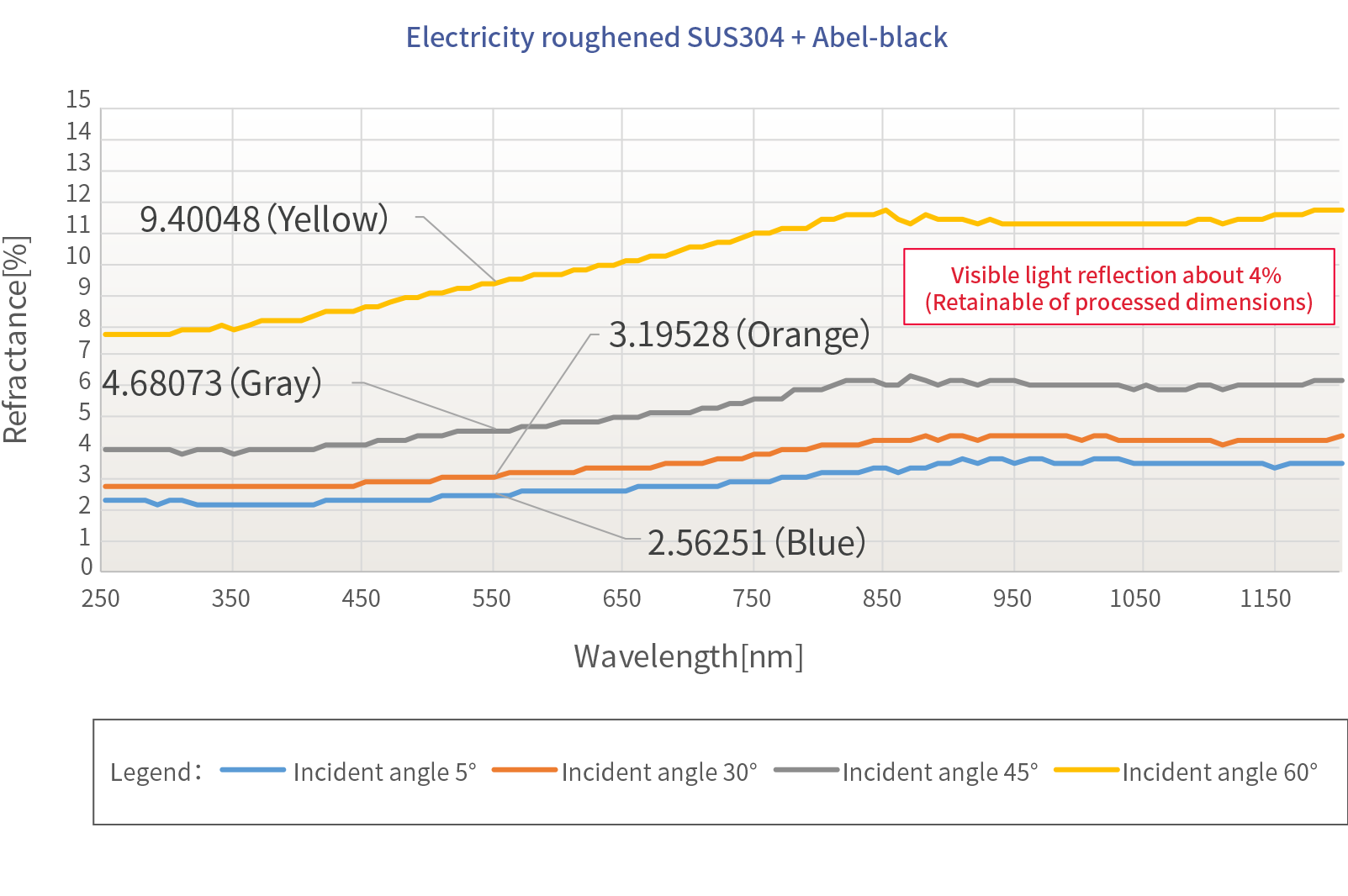

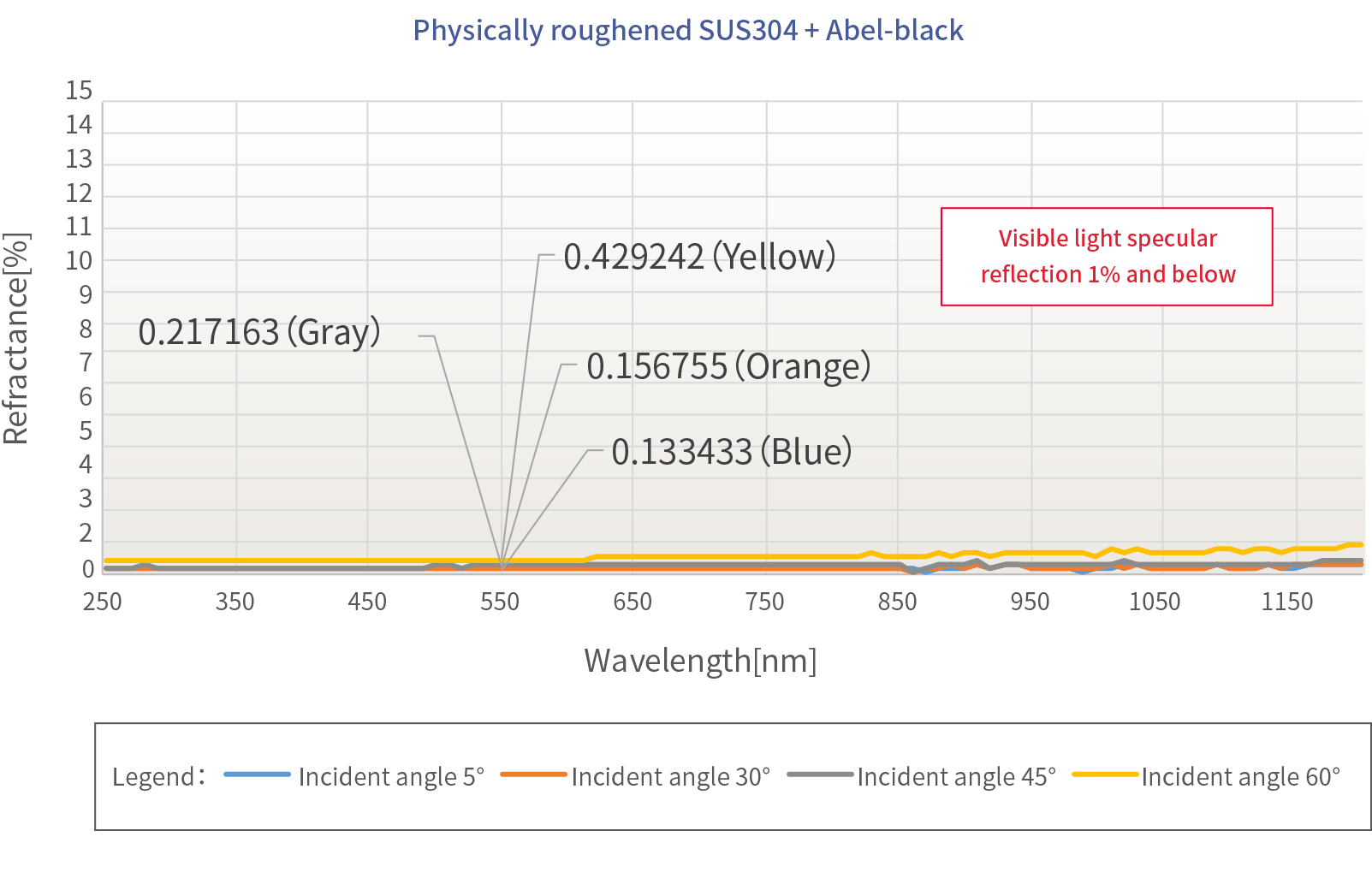

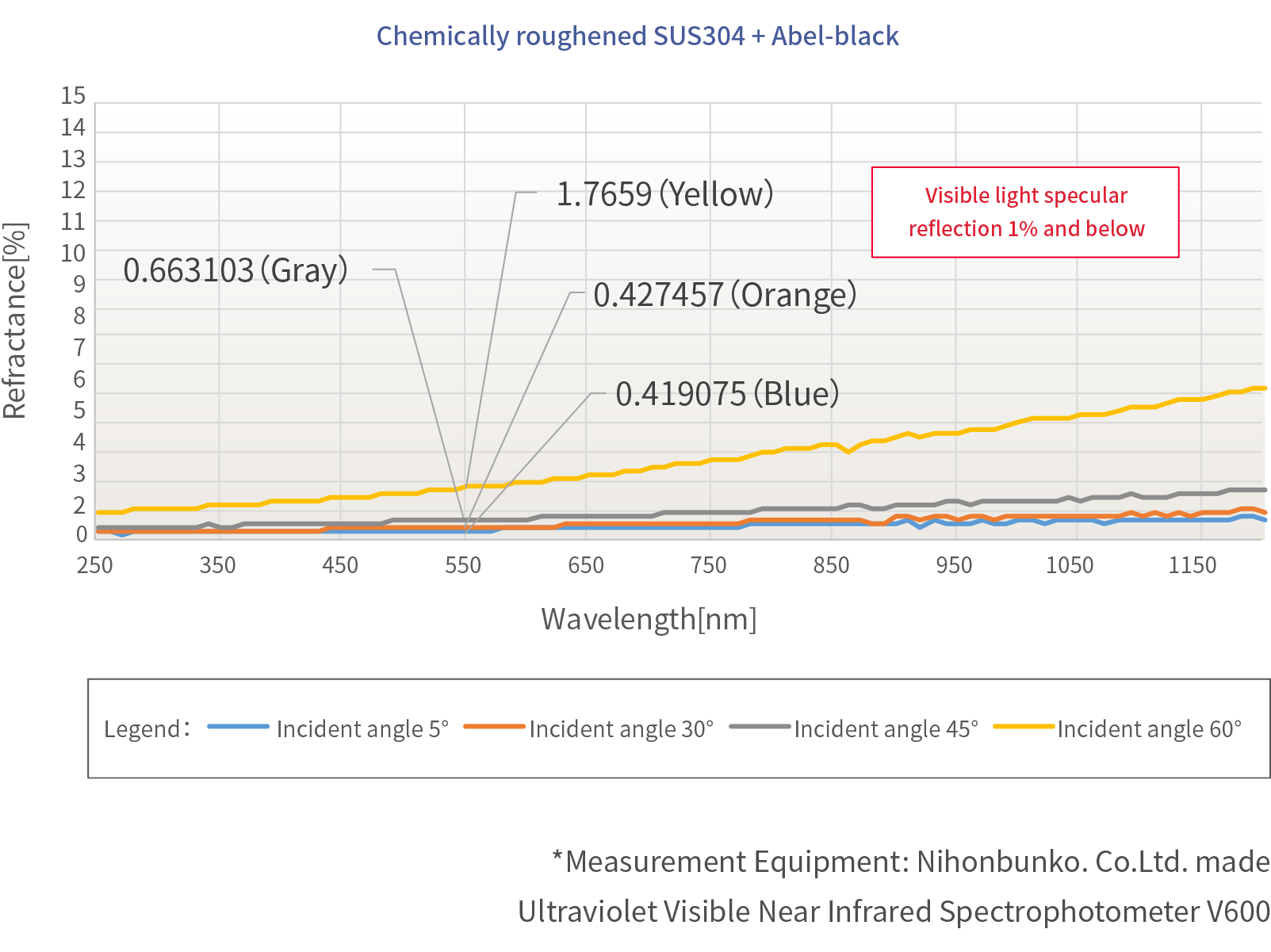

Also, Abel Black® can produce the surface of low reflection in response to customer demands by means of adopting additional process to roughening the base metal. As availability of treatment may depend on the process methods and shapes, kindly consult with us in advance.

Advantages of Stainless Steel Shades Over Anti-Reflective Products

- Blackened to the Edge

Light shields near lens units must suppress not only surface reflections but also edge reflections along the light path.

Abel Black can blacken edges completely, making it effective for preventing ghost images. Matte finishing is available as an option.- Advantages Over Resin Materials

Superior heat resistance with no dimensional change from temperature fluctuations (suitable for automotive cameras and camera modules).

Even ultra-thin materials prevent light transmission completely.- No Peeling Unlike Plating or Paint

The black oxide film forms by growing the stainless steel passive layer, providing exceptional adhesion with no risk of peeling.

No foreign metal or coating process eliminates contamination risk.

Environmentally compliant (RoHS/REACH regulations, etc.)- Thin Film Does Not Affect Dimensional Accuracy

Abel Black's film thickness is under 0.5μm with uniform coating even on fine details, making it ideal for precision optical components requiring tight dimensional tolerances.

Comparison of film thickness with other surface treatment

| Method | Basic film thickness (μm) |

|---|---|

| Hard chromium plating | 10μm |

| Black Ni plating | About 10μm |

| Non-electrolytic Ni | 5〜10μm |

| Hard anodized aluminum (black) | 40〜61μm |

| Black anodized aluminum | 15〜3μm |

| Abel Black® | 1μm and below |