Abel delivers reliable materials through strict quality control and sustainable processes

Reliable Precision

Certified to international standards and trusted worldwide

At Abel Co., Ltd., we continuously update our management system to maintain and improve product quality. We implement quality control based on ISO 9001 and JIS standards, ensuring products you can trust.

Meticulous Attention at Every Step

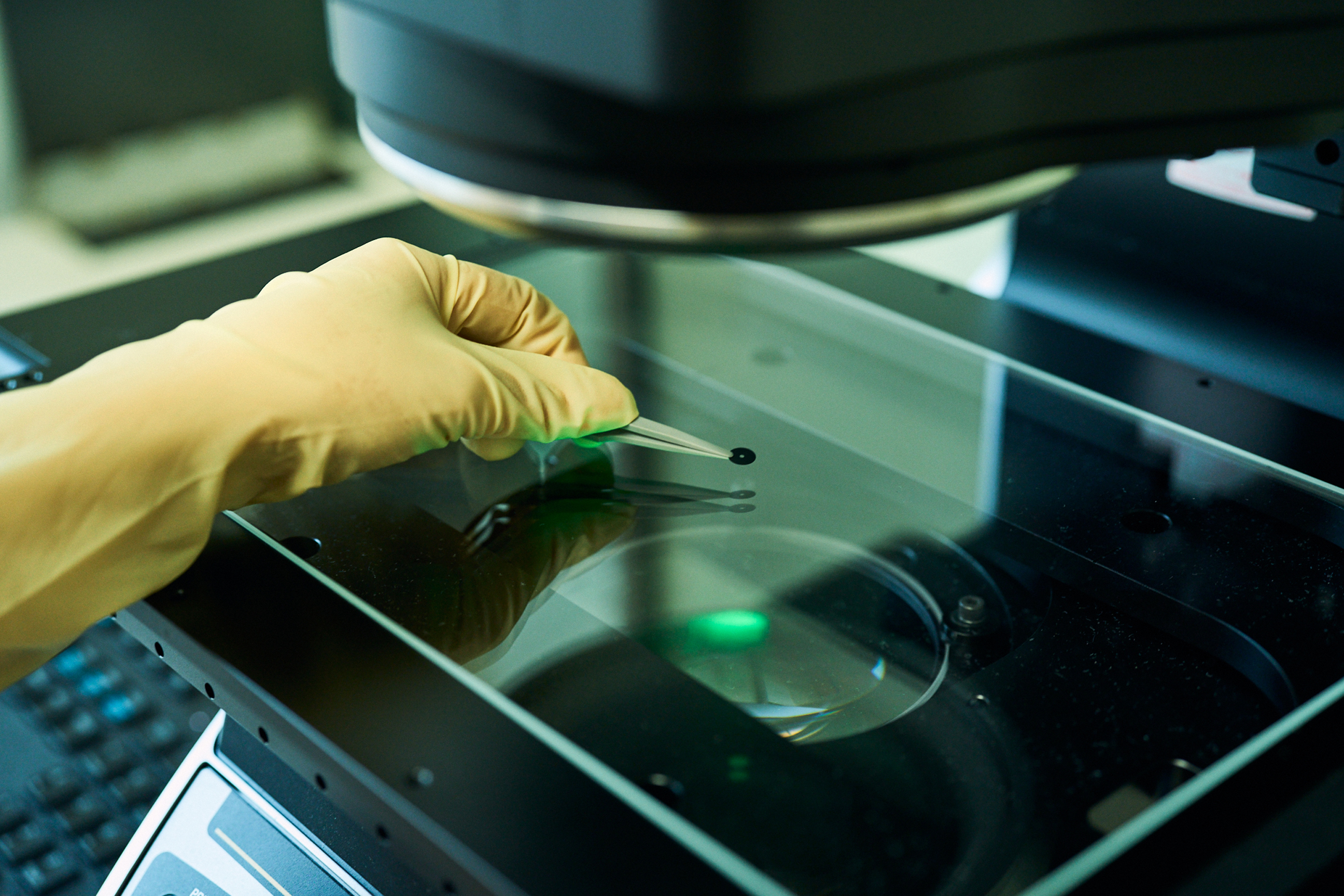

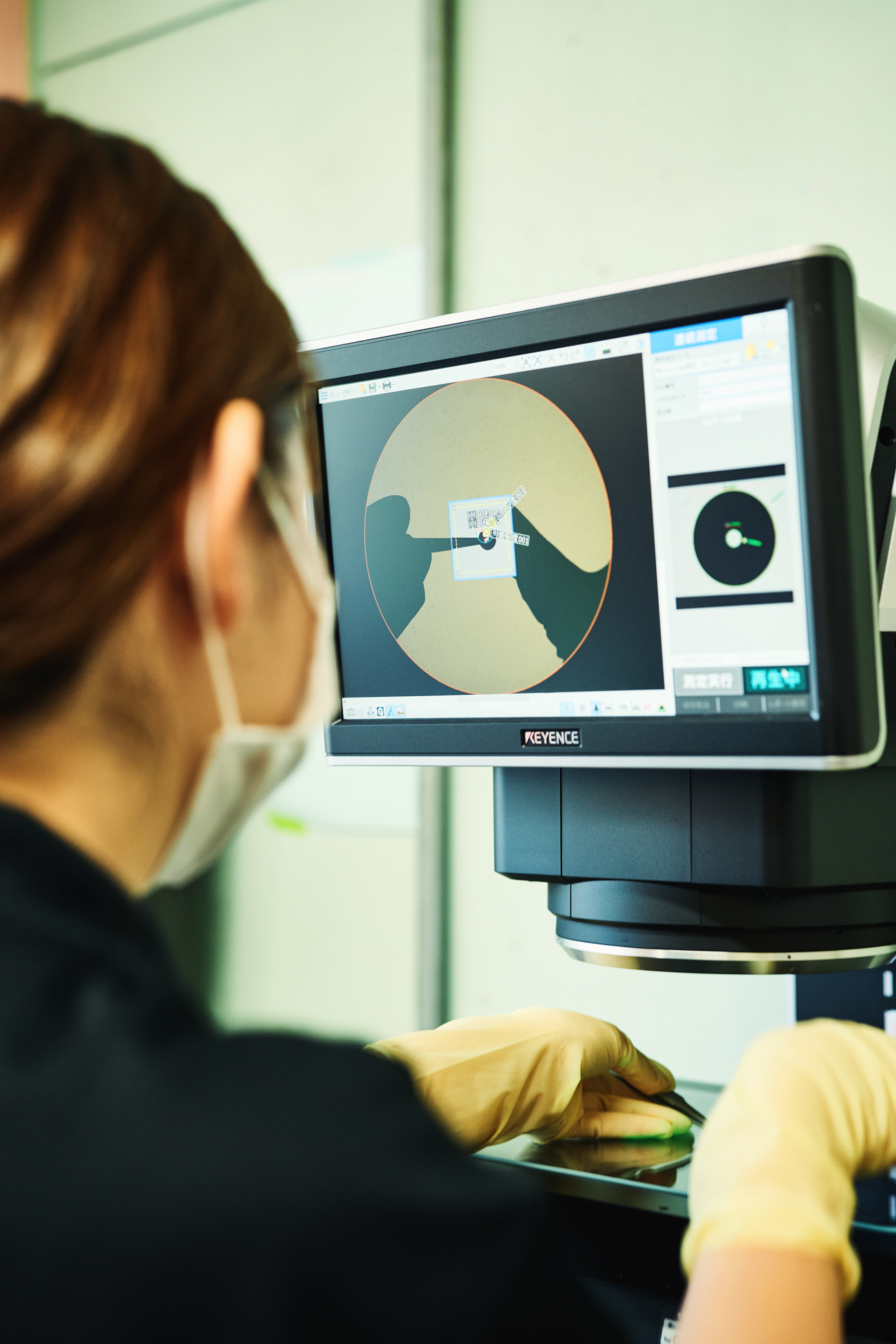

We maintain a thorough inspection system to develop and manufacture superior products, ensuring outstanding quality through advanced equipment

Materials with completed stainless-steel surface treatment undergo inspection using specialized equipment. Dimensions, gloss, color stability, weight, and cleanliness are checked at multiple stages, ensuring consistency and transparency throughout the production process.

-

A high-precision image dimension measuring system.

-

Measures lightness and chroma, quantifying brightness and color vividness. Used to check color consistency and reproducibility.

-

Measures color by breaking it down into red, green, and blue components. It provides a more general color measurement compared to the spectrophotometer.

-

Measures the gloss level of materials before and after surface treatment.

-

Accurately measures weight before and after processing, used to calculate dissolution amounts.

-

Primarily used to measure residual ion concentration after surface treatment.

-

Quality control integrated into the process

At Abel, quality is not only verified at the final stage but is embedded throughout every step of the process. From raw materials to final finishing, we have established a production system with checkpoints designed to detect and prevent defects early. Drawing on decades of expertise, we continuously refine and optimize our manufacturing methods to deliver reliable quality to every customer.

Abel Black® inspection system

-

The condition of each item is checked, and appropriate action is taken as needed.

・Inspection for scratches, deformation, stains, or uneven polishing

・Surface cleanliness check; if required, wiped with an organic solvent -

Removes surface oil through a dedicated degreasing process.

-

Fully removes any residual degreasing agents.

-

Processing is carried out under precisely controlled conditions.

-

Completely removes treatment solution; pH paper is used for verification.

-

Rinsed with deionized water (conductivity <1μS) to prevent water spots.

-

Dried with clean air or filtered heated air to prevent contamination.

-

Visual checks for scratches, deformation, stains, or color variation.

Quality is also verified using inspection equipment:

・Color difference management with a colorimeter

・Gloss measurement with a gloss meter

・Reflectance testing for optical components -

・Protective film application (for architectural materials, etc.)

・Wrapped in cleanroom-grade paper

・Sealed in polyethylene bags※Packaging method is determined in consultation with the client and follows specified requirements.

Inspection system for Electropolishing and Chemical Polishing

-

The condition of each item is checked, and appropriate action is taken.

・Inspection for scratches, deformation, stains, or uneven polishing

・If surface contamination is found, it’s wiped with an organic solvent as needed -

Oil and surface contaminants are removed through a degreasing process.

-

All traces of degreasing agents are thoroughly rinsed off.

-

The polishing method is selected based on the size, shape, intended use, and customer requirements.

-

High-pressure jet rinsing removes any residual chemicals, especially from tight spaces.

pH test strips are used to verify complete removal. -

When required, parts are immersed in nitric acid to stabilize the passive film formed after polishing.

-

Rinsed with deionized water (conductivity below 1μS) to prevent water spots or staining.

-

Clean air or filtered heated air drying prevents particulate contamination.

-

White-glove inspection ensures the surface is free of contaminants.

Visual inspection is also conducted for scratches, deformation, stains, or uneven gloss.Instrument-based evaluations include:

・Gloss measurement with a gloss meter

・Surface roughness measurement

・Spectrophotometric analysis for residual ions and oil

・Weight-based analysis of material dissolution -

・Wrapped in cleanroom-grade paper

・Sealed in polyethylene bags※Packaging is carried out according to the agreed method following client consultation.

※This is a standard process. Steps may vary depending on product requirements. Final procedures are determined in consultation at the time of order.